Midland Basin MudCube Installation

Stage 3 Separation provided a solids control solution outside of a conventional equipment design including the Stage 3 Separation MudCube—designed for high ROP drilling and low mud weights—to solve excessive base fluid dilution.

The Mission

Install a high performance MudCube filtration system that can exceed the customers performance specifications while also reducing their reliance on base fluid (diesel) dilution.

Drilling Fluid Challenges

Drilling fluid density is a critical component to oil and gas well drilling. Optimal drilling performance requires proper fluid densities to stabilize the wellbore and balance the downhole pressures the wellbore is experiencing.

Both increasing and decreasing fluid density can become extremely expensive, therefore it is crucial to find a cost-effective solution to maintain the density.

The Objectives

Stage 3 Separation is committed to finding solutions to our customer’s pain points. Through our engineered approach we not only reduce our customer’s overall cost but also reduce their environmental impact.

Improve first pass drill solids removal.

Recycle and reuse drilling fluid throughout project.

Reduce the amount of base fluid required for dilution.

The Solution

Stage 3 Separation’s proposal challenged the traditional centrifuge model of cleaning an already contaminated fluid. Instead, Stage 3 shifted the focused to preventing initial contamination of drilling fluid from drill solids by installing an equipment package with the MudCube™.

The installation included three Stage 3 MudCubes and a single 19″ bowl centrifuge. The MudCube suction point at the sand trap and settling pits ensured that all fluid from the flowline was processed through the MudCube. This method made certain that the entire circulating system was filtered through the MudCube screens and guaranteed first pass solids removal. The centrifuge was used to maintain mud weight as needed.

The Numbers

Reduced diesel consumption by 43%

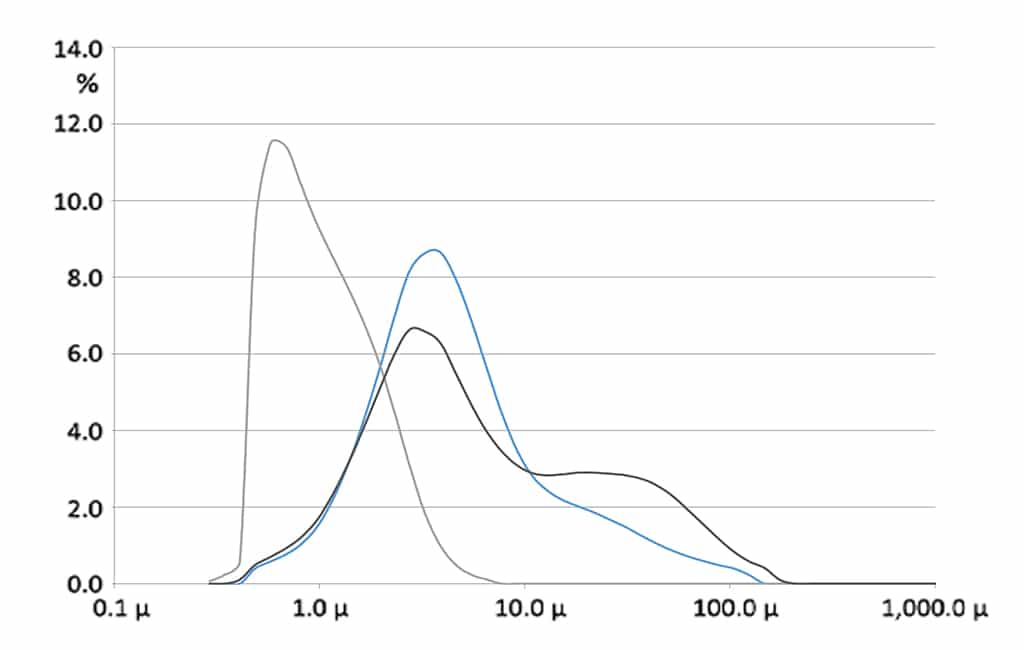

Improved Particle Size Distribution of the entire Drilling Fluid system

Saved customer $39,000 per well

The Process

- Flowline Shakers and Stage 3 Separation MudCube were dressed to the appropriate API screen size based on the customer’s density and viscosity specifications.

- During drilling operations, MudCube processed 100% of the volume from below the flowline shakers, ensuring that the entire volume was filtered at a very specific particle size.

- The big bowl centrifuge processed a percentage of the effluent from the MudCube, removing solids smaller than the MudCube cut-point.

- During periods of non-drilling, technicians would adjust the suction point of the MudCube to provide pit cleaning for the entire pit system, not just the sand trap and settling pits. This eliminated the need for pit cleaners at the end of each interval, saving time and money.

- Diesel dilution was only utilized according to the volume of new hole being drilled to maintain proper circulating volumes.

- As the mud system and drilling operations dictated, MudCube screens sizes could be updated to provide additional filtration or increase throughput.

- While not required in this application, MudCube enclosures can be sealed to both eliminate vibration noises typical of shale shakers and evacuate any gases found in the fluid to a safe zone for treatment.

The Conclusion

The successful installation of the Stage 3 Separation MudCube™ resulted in a significant reduction in base fluid consumption as well as reduced waste volumes when compared to historical wells. The result was a net savings for our customer of $39,000 per well and an overall reduction in environmental impact.

The Stage 3 Separation MudCube is a versatile system that provides value throughout Stage 3 Separation’s product lines. It’s flexible installations, high processing rates and enhanced Health, Safety and Environmental (HSE) features make MudCube an ideal filtration device for many industries. The enclosed process reduces noise to meet restrictive noise ordinances and captures gas to allow for evacuation to a safe zone for treatment. Whether being used in oil well drilling, construction projects or wastewater treatment, MudCube’s highly versatile installations make it a solution for many projects.

For more information about this project or how Stage 3 Separation – BOS Environmental Solutions can service your next project, please contact us today.