It seems that everywhere you go in oil and gas the latest buzzword at the moment is “automation.” The term has become so threadbare that often members of the same audience conclude radically different ideas of what automation truly means. When I think of automation, my mind immediately goes to the 1980s cartoon “The Jetsons.” In this futuristic cartoon, it seemed that nearly every task was completed by pushing a single button. From driving a flying car, washing your hair, or cooking your food; simply push the button and the rest of the process was… automated! So how did the term automation become so convoluted? Perhaps it’s because automation is often viewed as a one-step process. To reach that final Jetsons-like product, there are several iterations that must be made to introduce small pieces of automation until the entire process is complete. While the intermediary steps do not create the Jetsons-like automation, they do add automation to the product and are classified as such.

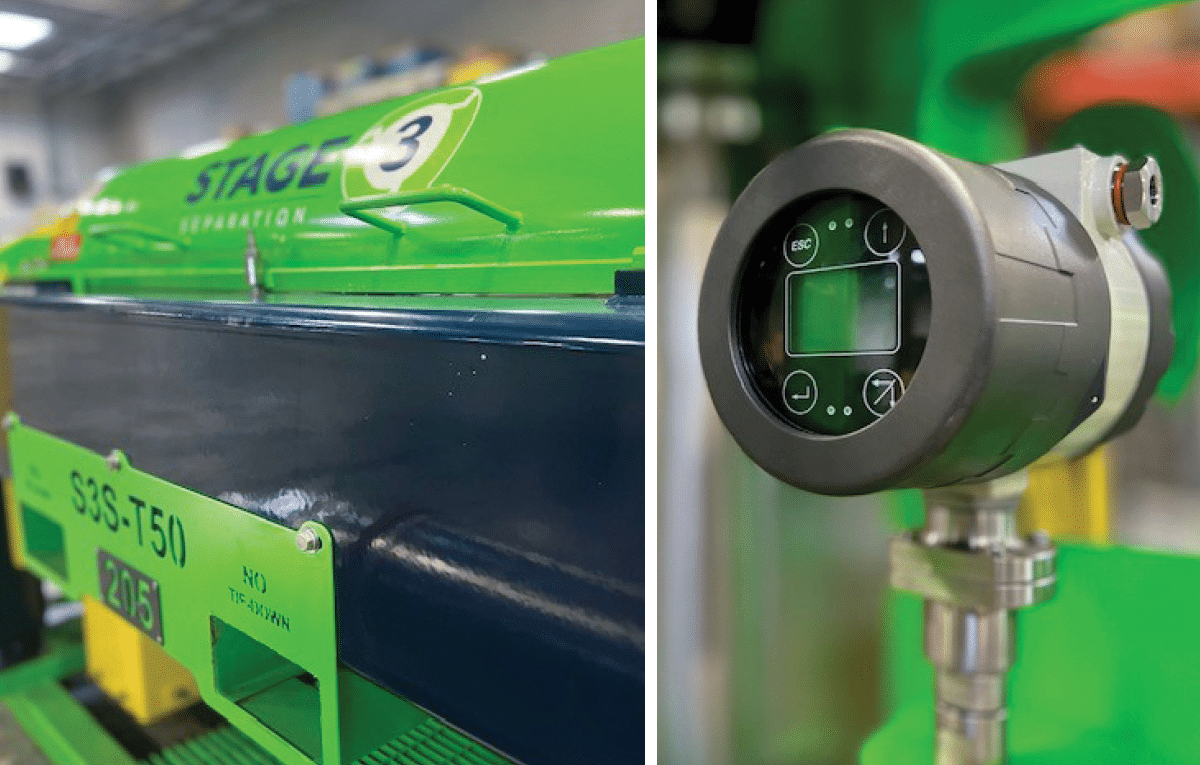

Stage 3 Separation has been planning, integrating, and testing automation in our solids control equipment for several years now. We have had both success and failures along the way, but each failure has led us down a path toward realizing our goal. Finally, after years of development, we have created the Stage 3 Separation Smart Centrifuge Package. This smart system is not one-step automation; however, it wasn’t designed to be (operating a 6,000 lb. centrifuge that is spinning at over 2,000 RPMs in an unfriendly environment such as a drilling rig may not be the right place for push-button automation). However, what we did do was to build logic into our machines gathered from multiple decades of experience and thousands of different data points. Combining our experience and data into the centrifuge automation program allows us to simplify the centrifuge operations for the general technician. They can now run the centrifuge in the same way the best solids control technicians would, without requiring 10+ years of experience to do so.

In addition to having optimized centrifuge run parameters for the technicians, our Smart Centrifuge Package allows remote monitoring of the equipment and processes. This includes centrifuge operating details, equipment health, feed, and effluent volume levels, as well as density and temperature. By monitoring each of these data points, we can calculate a complete mass balance for every gallon of liquid and solid that goes through our machines. Not only does this help us understand the efficiencies of our centrifuge operations, but it also gives us valuable insight into our waste stream volumes. By keeping a technician on location, we can continue to be vigilant for any problems that may arise. Because of the Smart Centrifuge Package technicians are no longer required to be highly experienced to produce exceptional results. By utilizing smart logic and remote viewing technology, Stage 3 Separation can ensure our customers are receiving high efficiency and increased uptime from the equipment and people in their backyards.

While our Smart Centrifuge Package is not designed to be the Jetsons’ centrifuge, Stage 3 Separation is leading the charge towards a smarter backyard. Perhaps someday soon our technology will leapfrog the theoretical Jetsons’ centrifuge, where a simple mouse click from thousands of miles away triggers our highly efficient centrifuge process. But until that time, we will continue to bring to market new and exciting innovations with real automation. Want to see how this technology can help on your next project? Contact us today for a free consultation.